Decades of Metalworking Excellence Supporting Your Business

Optimize your operations with customized hardware solutions. With Prime, you receive not just products, but our quality promise in every shipment. This commitment has made us the preferred manufacturing partner for global businesses.

Custom Metal Innovation – Powering the Next Industrial Leap

Who we are

Dependable Custom Hardware Built on Partnership

For over 30 years, we’ve been the trusted source for complete metal parts fabrication services

Every component meets strict ISO benchmarks across our full range of metalworking services: stamping, welding, casting and fastener manufacturing

From American factories to Middle Eastern projects—our ISO-certified components power global manufacturing

Frequently Asked Questions

Learn more here about mold design, making, and custom modifications.

What are the first steps to launching a custom metal parts project?

- Send us your drawings (2D or 3D), samples, or a comprehensive description, and we will assess production feasibility before presenting a preliminary quote.

- Should you not have technical drawings, we can deliver reverse engineering services, creating designs directly from your sample.

- Providing complete details—such as dimensions, tolerances, materials, and surface finishes—enables us to deliver a more accurate solution.Providing complete details—such as dimensions, tolerances, materials, and surface finishes—enables us to deliver a more accurate solution.

- We will assess your specifications and suggest the optimal manufacturing process—whether stamping, CNC, casting, or other techniques.

- Following project confirmation, we will develop a thorough mold design and proofing plan for your evaluation.

What is the mold design process?Can l take part in the confirmation?

- Our skilled mold design team employs UG, SolidWorks, and other advanced software to carry out structural design with precision and efficiency.

- In the mold design stage, we will share detailed 3D models or drawings with you for approval, ensuring all functional and dimensional specifications are satisfied.

- We can perform several iterations of structural adjustments according to customer feedback, proceeding to manufacturing only after final approval.

- During the design phase, we carefully assess production efficiency, tool longevity, and ease of maintenance to deliver reliable and cost-effective solutions.

- Following customer approval, the finalized drawings will be archived in accordance with our documentation standards to ensure consistent quality in subsequent manufacturing.

What is the typical lead time for mold production and proof sample creation? Do you offer expedited services for urgent projects?

- Making a standard mold usually takes 15–25 working days, but the exact time depends on how complex the structure is.

- For simple parts, die manufacturing and proofing can generally be completed within 7 to 10 working days, subject to design approval and material availability.

- We provide expedited tooling services, with sample delivery possible within a minimum of 5 working days, subject to project complexity and material availability.

- After the completion of the mold, we will provide samples to customers to confirm, confirm the error before mass production.

- Throughout the entire production cycle, our sales team will provide regular updates at each stage, including design, mold manufacturing, proofing, and more.

Is it possible to tailor metal components by choosing specific materials, adding branded logos, and applying custom finishes?

- Customized solutions in metal — from carbon steel and stainless steel to aluminum, copper, and zinc alloy — all tailored to your project requirements.

- Your logo can be applied to the surface of the parts through methods such as laser marking, embossing, or etching.

- We offer a wide range of surface treatment options, including electroplating, spraying, anodizing, polishing, and drawing.

- Choose the appropriate surface treatment program according to usage conditions, whether for corrosion protection, rust prevention, or enhanced strength.

- We also offer special packaging options, including company logo labels, blister boxes, and shockproof packaging, to meet your branding and shipping requirements.

Why Partner with Prime

Excellence is our standard

Our Advantages in Custom Parts Manufacturing

Quality Assurance

We strictly adhere to ISO quality standards, and has obtained ISO 9001 certification. This means that our production lines use advanced technology to make accuracy and precision possible. We have advanced measuring and testing equipment, able to check all imported materials and parts to meet your specifications. That's what makes our company stand out.

Learn more about our quality control systemFree Instant Quote within 24 Hours

Generally, quotations will be delivered in 24 hours after submitting email with clear information. You can get product price, freight, tax, delivery date, best processing method and transportation method, etc.

30+ Years in Parts Manufacturing

In the online custom parts processing has been 30 years, our engineers have accumulated rich experience. We can handle all types of projects.

Factory Direct Price & ISO9001 Quality Assurance

Our in-house facilities allow us to quickly complete your project. Factory lower price and fast lead-time. ISO9001 Certified Quality.

Fast Logistics

Own equipment, unlimited capacity, experienced engineers and flexible production systems allow us to create your prototypes and production parts in no time.

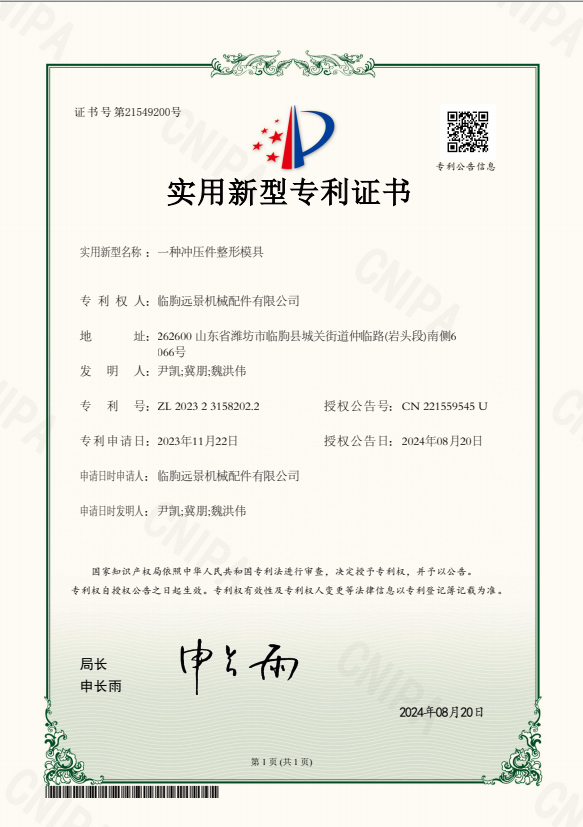

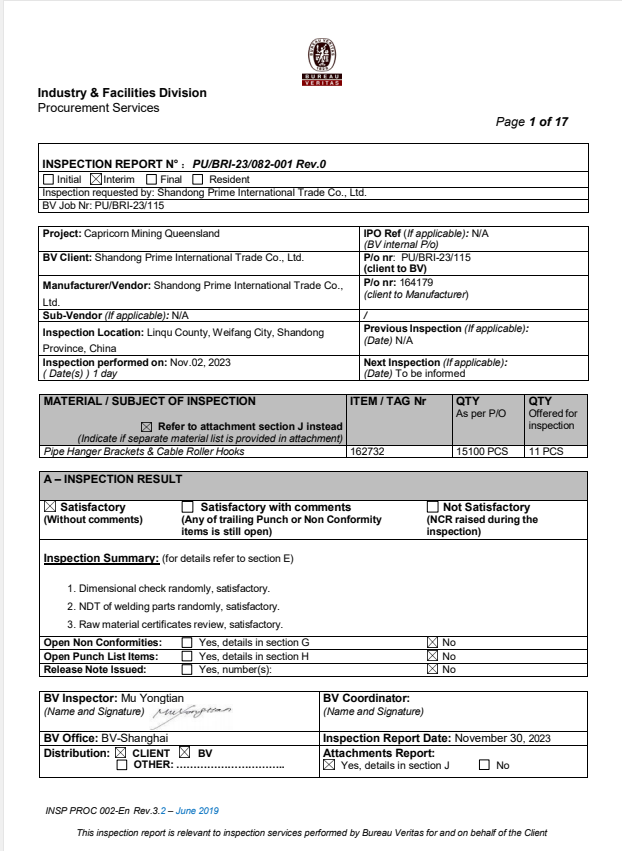

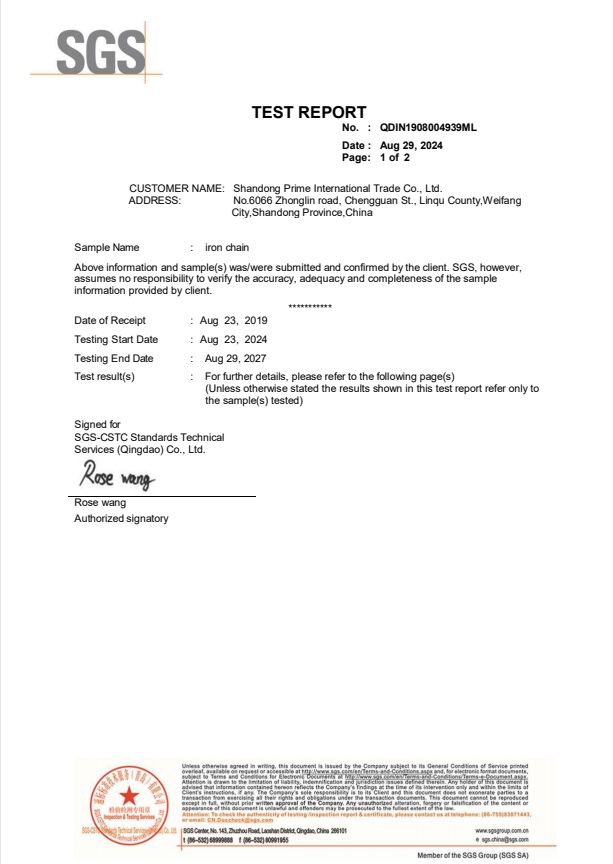

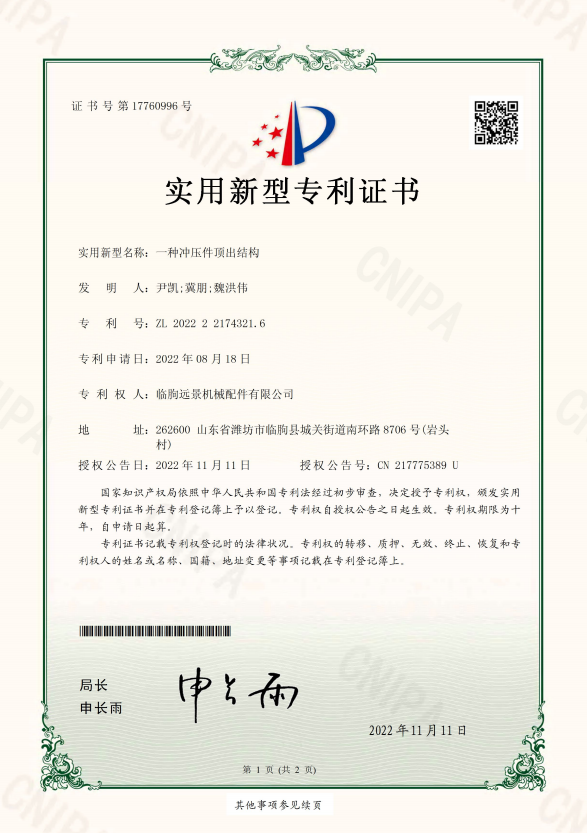

Certificates

What Our Client Said

Maximilian

Product Manager, PM

“Die Zusammenarbeit mit Prime hat unseren Fertigungsprozess erheblich rationalisiert. Ihre Präzision und schnellen Durchlaufzeiten waren ein Schlüsselfaktor für unseren Produktionserfolg.”

Kenta Sato

Purchasing manager,UACJ

“プライムとの協力により、製造工程が大幅に合理化されました。彼らの精度と迅速な納期は、私たちの生産成功の重要な要因となっています”

Elias Söderberg

Production Supervisor,Sandvik AB

“Att arbeta med Prime har avsevärt effektiviserat vår tillverkningsprocess. Deras precision och snabba handläggningstider har varit en nyckelfaktor för vår produktionsframgång.”

Receive a competitive quote within 24 hours

With Prime, you will receive a competitive quote within 24 hours — helping you save valuable time in sourcing decisions. Rapid response means you can compare costs, plan budgets, and accelerate your project schedule with confidence.

Simply Customize Metals

Finding top-quality custom metal parts doesn’t have to be complicated. At Prime, we guide you through it in three easy steps:

Three Decades of Trusted Production Experience, Delivered from Our Own Facilities

Custom-Designed Components Engineered for Your Specific Applications

Worldwide Delivery Network with End-to-End Logistics Services

Fast and Transparent Quotes with No Hidden Conditions

Your Designs and Information Stay Fully Confidential — Guaranteed

After you confirm the design and pricing, we’ll start production and manage the shipping—making sure everything arrives on time.

Reach out to us for a free quote and expert advice on your custom hardware needs. At Prime, we’ll provide the right solution for your project, ensuring quality and precision every step of the way.